Able to support a load weighing up to 350kg

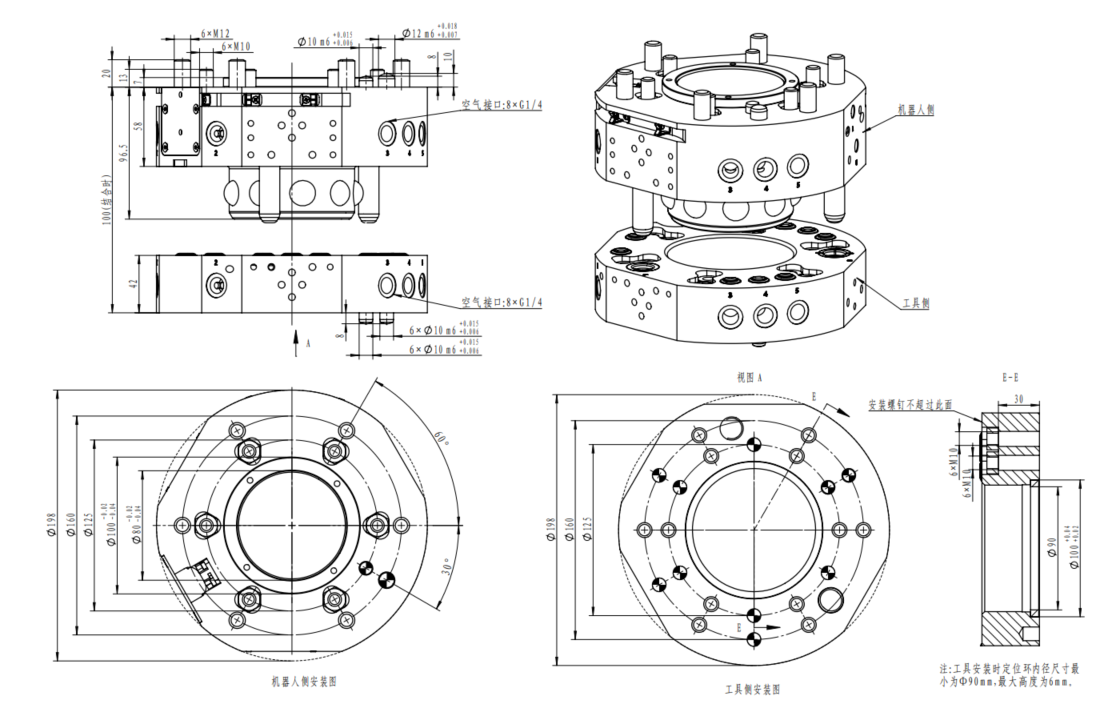

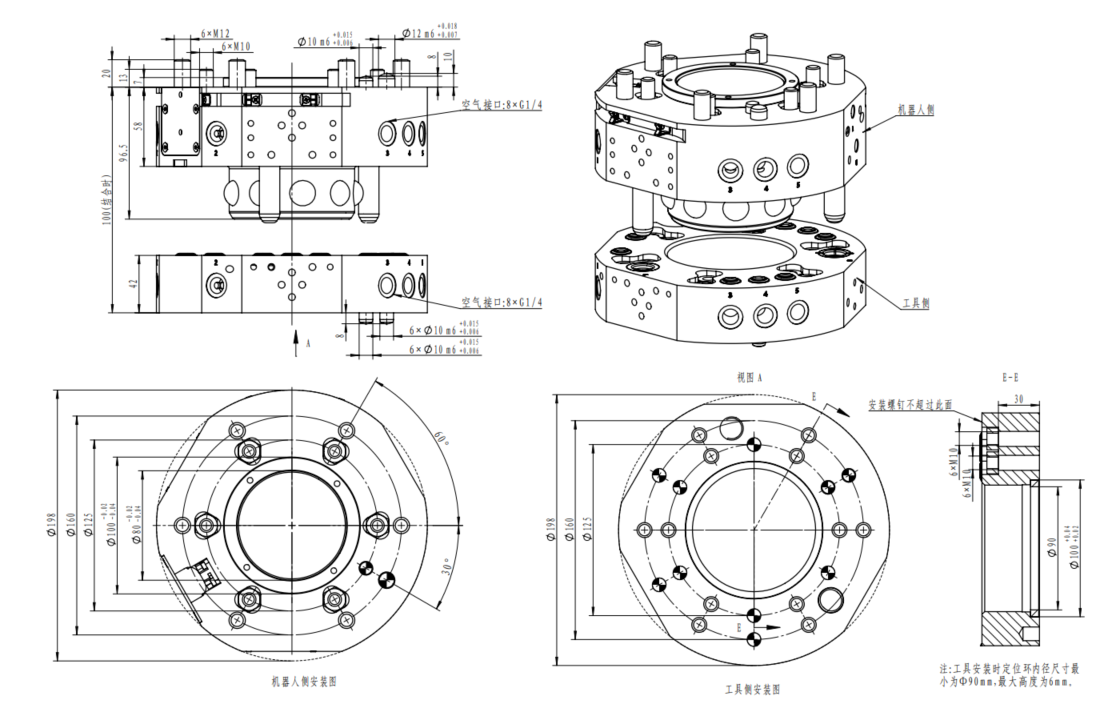

With 8 air channels, standardized modules and 3 sets of module mounting surfaces

Equipped with an unlocking sensor, a locking sensor and a face in-place sensor as standard

Overall dimension: Φ198mm×H100mm

Connected through flanges in line with ISO9409-125-6-M10/ISO9409-160-6-M12

| Main body | Payload | 350kg | |

| Repeat accuracy | ±0.02mm | ||

Allowable static moment | Bending moment | 2800N·m | |

| Torque moment | 2800N·m | ||

| Material | Main body | Aluminium alloy | |

| Locking mechanism | Alloy Steel | ||

| Shape size (locked) | φ198mm×H100mm | ||

| Product weight | Robot side body | 7.05kg | |

| Tool side body | 2.65kg | ||

| Lock/Unlock mechanism | Spring self-resetting locking | ||

| Lock/Unlock Pressure | 0.45~0.8MPa | ||

| Permitted temperature and humidity | 0-55°C,0-95% | ||

| General | Air port | 8×G1/4(Non-self-sealing) | |

| Control body | Cylinder motion sensor | Lock sensor | A proximity switch Inside (DC three-wire) |

| Unlock sensor | A proximity switch Inside (DC three-wire) | ||

| Surface detection sensor | TOOL Cirming | A proximity switch Inside (DC three-wire) | |

Integrated solenoid valve control module, used to control the quick-change disk locking/unlocking

Integrated tool air supply, only one way to realize the quick-change, tool air supply

Integrated pressure detection, real-time detection of air supply pressure

A variety of switch trigger options to suit different scenarios

Patented safety circuit, safety level up to PL d Cat 3.

Quick-change safety circuit to realize tool unlocking at a fixed point.

The air channel supports one side self-sealing function.

Standard interface: G1/4 air channel, maximum diameter 5mm.

Unidirectional self-sealing on the R side after disconnection.

Modular design for quick and easy maintenance.

Single module provides 5 air passages.