Application Background

With the improvement of environmental protection consciousness, the traditional manufacturing method requires a lot of resources and energy such as water, electricity and chemicals, injection molding processing is less expensive and less polluting to the environment, so injection molding processing will become the mainstream of the future manufacturing industry.

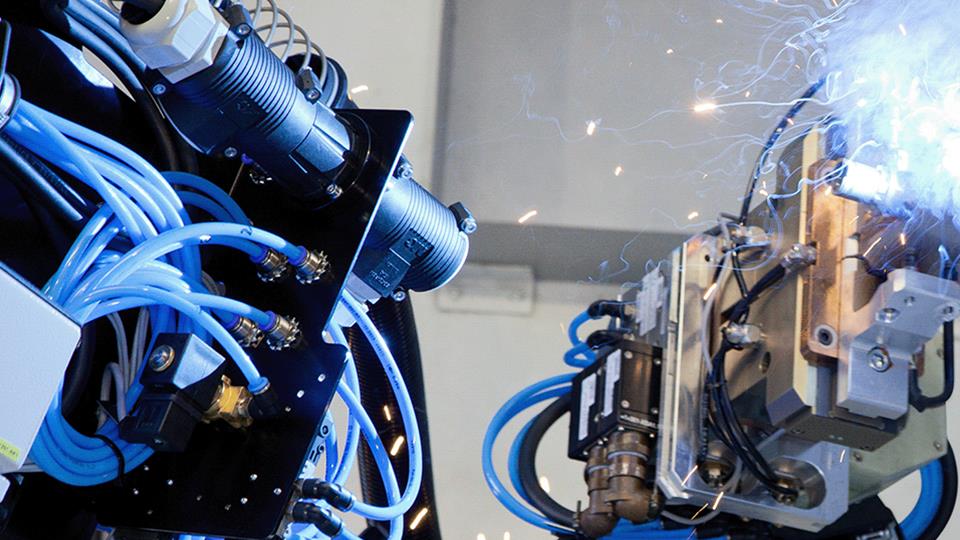

Magnetic mold changing system realizes the quick mold up and down through the cooperation of electromagnet and permanent magnet. Accelerate injection molding processing production efficiency. Can quickly produce a variety of plastic products, to adapt to the rapid changes in market demand, so injection molding processing will be widely used in electronics, automotive, medical, aviation and other segments. With the development of big data, cloud computing, the Internet of Things and other new technologies, injection molding processing will be combined with digital processes, resulting in more new plastic products and production methods, providing more new solutions for the manufacturing industry.